Ultra-high pressure sterilization secrets: insight into 600MPa aseptic innovation technology

With the continuous improvement of food safety and quality assurance requirements, ultra-high pressure sterilization equipment has gradually become the darling of the food processing industry. This technology relies on a high-pressure environment to effectively kill microorganisms, avoiding the impact of high temperature on food flavor. This article will analyze in detail the working principle of ultra-high pressure sterilization equipment and its aseptic processing mechanism to help you gain a deeper understanding of this innovative technology that subverts tradition.

1. Overview of ultra-high pressure sterilization technology

Ultra-high pressure sterilization (HPP, High Pressure Processing) technology is a method of using extremely high pressure to act on food, causing microorganisms to lose activity, thereby achieving a sterilization effect. Unlike traditional heat treatment, HPP maintains the nutritional components and flavor characteristics of food while completing sterilization. This technology is widely used in the processing of fruit juice, dairy products, meat products, etc.

1. Non-thermal sterilization: Traditional sterilization methods rely on high temperatures, but this can easily have adverse effects on the nutritional components and taste of food. Ultra-high pressure sterilization breaks through this limitation and inhibits microbial activity through mechanical pressure rather than heat energy.

2. Pressure level: The working pressure generated by ultra-high pressure sterilization equipment is usually between 100MPa and 600MPa, which can effectively destroy the cell membrane structure of microorganisms and make them lose their activity without affecting the quality of food.

3. Application scope: It is suitable for various liquid or solid foods, such as juice, dairy products, meat, vegetables, seafood, etc. Its effectiveness is not limited to sterilization, but also can reduce the use of chemical preservatives in products and extend the shelf life of food.

2. Working principle of ultra-high pressure sterilization equipment

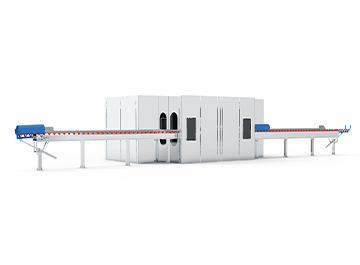

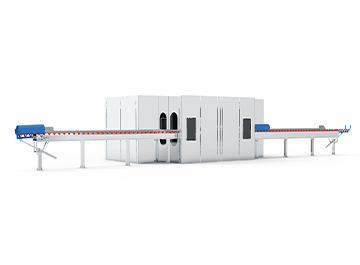

The core of ultra-high pressure sterilization equipment lies in its efficient pressurization system, which inhibits the growth of microorganisms through uniformly applied pressure. The following is the detailed working process of the equipment:

1. Pressure generation and transmission

Ultra-high pressure sterilization equipment uses a booster pump as the core component, and increases the pressure to the required level through hydraulic principles. The pressure is transmitted in an isostatic manner through a high-pressure fluid (usually water) to ensure that the pressure acts evenly on the food. The whole process is carried out in a closed sterilization chamber, thus avoiding the intervention of external pollution sources.

2. Food preparation and packaging

The food to be processed needs to be cooled in advance and then packed into pressure-resistant packaging. These packages are usually made of high-strength, pressure-resistant materials, such as special polyester films, to ensure that they will not break under ultra-high pressure.

3. Pressurization process

The food package is placed in a high-pressure chamber and continuously pressurized to a predetermined value (about 600MPa) through a hydraulic system, and the pressure is maintained for a preset period of time (usually several minutes). This stage is the key to ultra-high pressure sterilization. The pressure not only effectively kills most pathogens and bacteria, but also destroys acidogenic bacteria, molds and yeasts at the cellular level.

4. Depressurization and removal

After timing, the equipment slowly depressurizes to normal pressure and removes the packaged food from the pressure chamber. Food treated with ultra-high pressure does not require additional heating steps, thereby retaining more nutrients and original flavor.

3. Mechanism and advantages of 600MPa aseptic treatment

1. Microbial killing mechanism

Under ultra-high pressure, the membrane structure of microbial cells is mechanically destroyed, which can lead to leakage of bacterial contents and eventually cell death. At the same time, high pressure can also change the three-dimensional structure of enzymes, inhibit their biological activity, and further improve the sterilization efficiency.

2. Food quality maintenance

High pressure treatment cleverly avoids the damage of temperature to food quality and effectively protects food texture, taste and nutrition. Studies have shown that ultra-high pressure can maintain more than 90% of vitamins and antioxidants in food, making it one of the mildest sterilization methods currently.

3. Environmentally friendly and sustainable

Compared with traditional sterilization methods, ultra-high pressure sterilization does not involve heat energy consumption, which greatly reduces carbon emissions in the production process. Especially for fruit juice and other foods that are easily oxidized or rich in volatile components, HPP technology is particularly suitable.

4. Improved market competitiveness

No chemical additives and healthy preservation have become important demands in the modern consumer market. Ultra-high pressure sterilization technology not only extends the shelf life of food, but also enhances the market competitiveness of merchants, and products can be exported to international markets with strict requirements.

IV. Application cases and prospects

1. Application cases

Globally, many well-known companies have successfully adopted ultra-high pressure sterilization technology. For example, the UHP juice brand in the United States has taken a leading position in the juice industry. Domestic companies have also introduced HPP technology in dairy and seafood processing, achieving significant quality improvements.

2. Prospects

With the maturity of the consumer market and the demand for high-quality food, ultra-high pressure sterilization technology is bound to continue to expand globally. In the future, with the decline in equipment costs and technological advances, ultra-high pressure sterilization is expected to become one of the standardized processing methods in the food industry.

Summary

The advent of ultra-high pressure sterilization equipment provides a new technical path for aseptic processing. On the one hand, it ensures food safety, and on the other hand, it also maintains the natural flavor and nutritional value of food. Looking to the future, the promotion and application of ultra-high pressure sterilization technology will inject a steady stream of power into the global safe, efficient and environmentally friendly food processing industry.